Listed below is more information about our frames and how to contact us.

|

|

| Ed at the farmstand |

|

| If you would like to talk about frames and other options please call or email. The phone number is 603-476-8829 or email:ed@ledgewoodfarm.com. I will be happy to talk about production techniques using heated and unheated greenhouses and high tunnels. We also sell frames for livestock housing, storage, growing and overwintering nursery stock and covering swimming pools.

|

Tomatoes are one of the most profitable crops to grow in a high tunnel or greenhouse. We have been growing greenhouse tomatoes at the farm since 1960. Tomatoes can be either trellised on strings or grown with a basket weave system.Additional crops include peppers, vinecrops, winter greens, sandwich onions, berries, brambles, and tree fruit.

|

|

| Double row trellis tomatoes |

|

|

|

| Sliding door on a bedding plant house |

|

| We have many bedding plant customers who use our frames for heated production, unheated cold frames and retail space. You can add flood/trough watering systems, rolling benches, monorails, and hanging basket racks. We can provide the tubing to complete many of these systems.

|

PRODUCTION AND MARKETING OF HIGH TUNNEL CROPS

Ed Person

Ledgewood Farm

132 Old Mountain RD, Moultonborough,NH 03254

ed@ledgewoodfarm.com

The early production of high value crops is a focus at Ledgewood and to achieve that goal we use heated greenhouses, high tunnels, row covers and dry south facing fields. The focus of this talk is on the high tunnels but without the other components of our production system the tunnels would be less important. The farm sells direct to our customers through a farmstand that is open six days a week from mid-June until early September. The only crops that would be ready in mid-June without the greenhouses and tunnels would be lettuce, greens, and strawberries. The greenhouses produce tomatoes and jingle bell peppers at this time. The tunnels add cucumbers, summer and zucchini squash, small onions, and cut flowers. Two weeks later there are artichokes, eggplant, and sandwich onions. Other crops with potential include carrots, beets, snap peas, and broccoli.

The short season at our farmstand makes it even more important to have early production of normally late season crops that tend to have high value. Almost half of our season would be over before many of the crops that people want more than once a week would be ready if we relied only on field production. Customers seem content to buy lettuce once a week but when you can tempt them with a wide selection they will return frequently as the trip becomes more worthwhile. Even with row covers there is a much higher risk of frost damage than there is with high tunnels because of the increased distance of the crop from the outside environment. We use infrared retaining poly on all of the tunnels and greenhouses to help maintain elevated inside air temperatures. The other factor is that the tunnels can be covered early which speeds warming and drying of the soil for early planting. The last two years have been extremely cold and wet but we were able to have early production from the tunnels. We didn’t harvest peas until June 29th in 2011 because of the wet spring and delay of field planting, but still had cucumbers by mid-June.

The following sections focus on four crops that tend to be of the highest value. The first section describes in basic detail the system we use to produce the crops and the second section provides some insight into the value of the crops. One important factor in our plan is that we are not afraid to ask a profitable price for all of our produce. Our customers need to be aware that it costs more to produce early crops and we must remember that highest quality is the only crop you should market.

Growing Methods for Season Extension

Ledgewood Farm 2011

The production of crops inside protective structures has been an accepted technique for many years. The benefits include increased production and extended periods of crop harvest. In some cases higher quality is also achieved. Any number of crops can be produced under cover. The most common are high value crops such as tomatoes, peppers, vinecrops, and cut flowers. The techniques to produce these early crops are outlined below.

The most important aspect in the production of any crop is maintaining high soil fertility and consistent soil moisture levels. Most greenhouse systems rely on a combination of preplant and continual applications of fertilizer. The system that Ledgewood Farm uses includes cover crops during the off season and composted organic fertilizers. In most cases additional fertilizer applications during the growing cycle are not needed. Drip or overhead irrigation systems are installed in all houses.

Tomatoes. The production of early tomatoes is the quest of almost every farmer. Using greenhouses with heating systems is the best way to produce early crops. Another option is to use unheated high tunnels to gain up to a month earlier crop over field production.

Greenhouse space is precious so many growers’ plant higher densities than they would field crops. Allowing about four square feet per plant and trellising or using basket weave systems is common. The seeds are planted into 162 cell plug trays and then transplanted into four-inch pots after three weeks. Ledgewood Farm transplants six- week old plants into the greenhouse. Plants are placed in the greenhouse about ten weeks before harvest. Mulch and drip irrigation systems keep the foliage dry to reduce mold growth on the plants. Trellised plants are tied and suckers removed on a weekly schedule. Basket weave strings are added as needed and only the lower suckers are removed.

Heat and ventilation control is vital for the production of a healthy and abundant crop. The key is to maintain low humidity in conjunction with high soil moisture. Pollination is a large problem with early plantings so bumblebees are placed in the houses. Later plantings that use natural ventilation (roll-up sides) generally pollinate from the wind and other insects. Temperature levels are maintained between 60 and 80 degrees Fahrenheit.

Peppers. The peppers are grown without heat. The miniature Jingle Bell peppers ripen from green to red by the end of June and that is early enough for my markets. The full size bells are harvested green also beginning at the end of June.

The system that Ledgewood Farm uses includes drip irrigation, woven ground fabric, trellis strings and a high plant density. Seeds are placed in 288 cell plug trays and transplanted into four-inch pots about three weeks later. Eight- week old plants are placed in the greenhouse eight weeks before harvest. The plants are spaced one foot in the row with three feet between rows. Some of the larger bell varieties may require increased spacing. The most profitable variety is the Jingle Bell that is harvested red. The attached financial analysis details the gross return. One pepper plant will produce about 40-60 red peppers between June 30 and September 10. Temperature control is important to insure high pollination and at the same time maintain high night temperatures. Plenty of ventilation and even watering are important to reduce blossom end rot and sunburn. The plants are trellised on strings using plant clips so that the weight of the fruit doesn’t bend the plants over and scar the fruit on the ground.

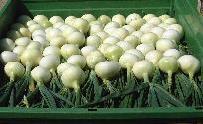

Sandwich Onions. The sandwich onions are grown in beds with four or five rows in each bed and six-inch on center plant spacing. There is an overhead watering system with low volume sprinklers. The beds are covered with one-mil black plastic. The onion plants are germinated in 288 cell trays and transplanted into 48 cell trays after about three weeks. The plants are transplanted into the house after about eight weeks. A hole large enough to allow water to seep down the plant stem is created. A drip system would work but it has to have multiple runs per bed. The house is kept warm at night by closing the roll-up sides. Cool day temperatures are maintained to help with strong stems and lower chances of mold forming. The varieties that Ledgewood Farm grows are Ailsa Craig, Walla Walla, and Mars. Harvest begins at the end of June and continues for about a month. At that time the field grown onions are ready to be harvested.

Flowers. The fresh cut flowers that are planted into the houses are generally annuals with short days to maturity. The most popular are snapdragons, zinnias, asters, statice, and celosia. Large stem size and abundant early blooms are important. The seeds are germinated in a heated greenhouse in 288 plug trays and transplanted to four-inch pots about four weeks later. The four-inch pots are used so that a larger plant is placed in the unheated house around May first and harvest begins by the end of June. Approximately twenty stems are cut from each plant by late July when the field harvest begins. The plants are placed three rows to a bed and the beds are on four-foot centers. The taller plants like snapdragons and zinnias are supported by basket weave or six-inch mesh suspended about one foot above the ground. Ground fabric and drip irrigation is also used.

Other Crops. The other crops that Ledgewood Farm grows inside the houses include artichokes, cucumbers, Summer and Zucchini squash, muskmelons, and eggplant. Cucumber is the most profitable of this group. The cucumbers are trellised on strings and are capable of producing forty or more fruit on each plant.

Aluminum window screen has become a part of the production system. The reduction of insect pressure has increased the production of some crops. The exclusion of potato beetle from eggplant is one example that reduces the insect pressure to levels where hand picking of the beetles becomes viable. Some beetles still find their way under and around the screen. The striped cucumber beetle is becoming a major pest because it vectors bacterial wilt and only small populations can have a devastating impact on plant health. Last year we had zero striped cucumber beetles in our tunnels. The screen works great to keep Japanese beetles away from cut flowers as well. One grower produces all of his broccoli and cabbage inside screened houses to exclude cabbage maggots and worms. The only limitation for the use of greenhouses as an aid in season extension is ones imagination.

Financial Analysis of Four High-Tunnel Crops

The following chart offers insight to the value of the four selected crops for tunnel production. Each example is based on the production from a 21-foot by 96-foot unheated high tunnel for early season production.

The most important aspect of any crop is the ability to market it for a profit after considering the added costs when using a high tunnel or greenhouse. Production is generally increased inside the high tunnel. The prices shown are those charged at my farm stand during the 2011 season. Every area has different pricing pressures, but Ledgewood Farm has educated our customers that if they want early local produce, the costs will be higher than crops produced without tunnels. In some cases, the crop is harvested for a short time in the tunnel and then we move to outside production areas. Other crops are harvested for the entire season and supplemented with outside crops.

The system that Ledgewood Farm uses to produce crops in tunnels includes woven polyethylene fabric, drip irrigation, and a trellis or support system. The exception is sandwich onions, which use one-mil black plastic mulch and an overhead irrigation system.

The chart below uses conservative production numbers for all crops except sandwich onions, which are limited by their one- time harvest. Ledgewood Farm normally harvest twenty stems from most of the flowers before the field cuts are ready. Many growers attain higher tomato production by trellising and increasing plant density for a short season, which reduces the number of clusters needed per plant.

Ledgewood Farm data 2011

| |

Cut flowers

|

Jingle peppers

|

Sandwich onion

|

Tomatoes

|

Number of plants

|

1,350

|

630

|

3200 |

360

|

Total crop produced

|

2,700

|

25,200

|

3200 |

3,000

|

Unit size

|

10 stems

|

each

|

each

|

Pound

|

Price/unit

|

$3.00

|

$.20

|

$.79

|

$3.99

|

Gross income

|

$8,100.00

|

$5,040.00

|

$2528.00

|

$11970.00

|

Income/foot ²

|

$4.01

|

$2.50

|

$1.25

|

$5.94

|

Time of season

|

6/25-9/5

|

6/30-9/5

|

6/25-8/10

|

7/15-9/5

|

Ed Person owns and operates Ledgewood Farm, a 15 acre retail vegetable operation in central New Hampshire. The farm also manufactures greenhouses and high tunnels for the commercial market. The farm has been in his family since 1947 and he has manufactured greenhouses since 1987. The business operates with two year round employees and five seasonal employees.

|

|

| Early onion production from a high tunnel. |

|

|

|